Modernization of furnace automation equipment .

Modernization of furnace automation equipment .

CJSC “Automated Systems and Complexes” has implemented a project “Modernization of furnace No.1 automation equipment” at JSC “Vyksa Metallurgical Plant”, Vyksa, Nizhny Novgorod region. ASC acted as the main contractor in this project.

Scope of executed works:

- Design preparation and software development.

- Supply of process equipment, information network components, equipment and materials for electrical installation and commissioning.

- Installation of electrical equipment, parts of gas ducts and air ducts, impulse piping and water piping used for water supply to water traps.

- Commissioning.

During installation and commissioning the following equipment was replaced and put into operation: pressure and temperature transducers, relay sensors for Instrumentation and Control system, actuators in the gas duct and air duct areas of 5 furnace heating zones. Analog regulators and relay circuits were replaced by a state-of-the-art automated process control system based on Siemens Simatic S7-400 PLC with distributed IO stations.

Modernized automated process control system provides:

- Monitoring and control of temperature and gas-air ratio in 5 heating zones;

- Monitoring and control of pressure in furnace chamber and flue;

- Monitoring and control of water level in furnace water trap;

- Collecting, archiving and visualization of process parameters and furnace equipment operation modes;

- Visualization of billet position in the furnace chamber;

- Analyzing and providing furnace performance data per shift and per day;

- Data transfer to the central MES system (manufacturing execution system).

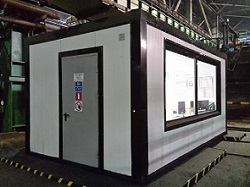

CJSC «ASC» designed and manufactured a room for control consoles. Communication with the operator is possible due to two automated workstations based on industrial PCs installed in the console room.

Console room was delivered to JSC “VMZ” ready for service.

Main equipment of the automated process control system is installed in RITTAL cabinets located in the console room and near the furnace.

An emergency transfer switch and a group APC UPS are used to provide uninterruptible power supply for automated process control system equipment.