11.03.2016

11.03.2016 Revamping of ventilation system for electric motors of rolling mill stand main drives.

ASC specialists completed implementation of frequency converters for main drive motor ventilation system, rolling mill stand aspiration system and pump soft starters in scale pits No.1 and No. 2 of the H-beam rolling plant. New system allows for regulating ventilation efficiency depending on the temperature of the main drive motors and reducing aspiration system efficiency during roll change, repair or unplanned downtime. This leads to significant energy saving.

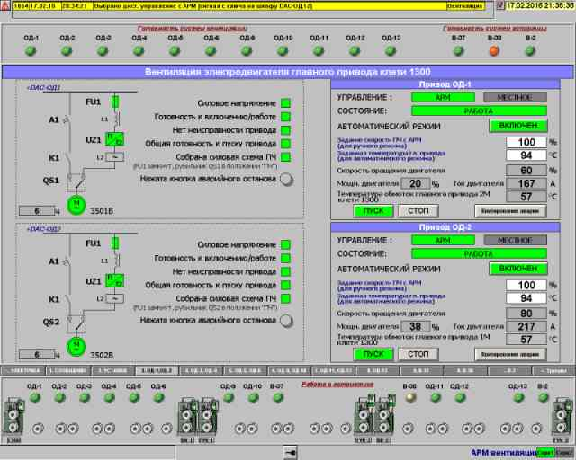

Motor ventilation system revamping included installation of cabinets with frequency converters in addition to existing contactor and relay circuits. After revamping ventilation is by default controlled from frequency converter (rotational speed is set up in PLC). Old contactor and relay circuits can be used for each drive as spare control circuits. Siemens Simatic S7-300 PLC is used as a master controller, frequency converters and soft starters used in the system are produced by Schneider Electric.

Revamped main drive ventilation system and rolling mill stand aspiration system allow for:

- regulating ventilation efficiency depending on the main drive motor temperature;

- reducing rolling mill stand aspiration system efficiency during roll change, repair or unplanned downtime;

- collecting, archiving and visualization of process parameters and operating modes of ventilation and aspiration systems;

- metering electric energy consumed by ventilation and aspiration drives.