16.03.2016

16.03.2016 Unloading device.

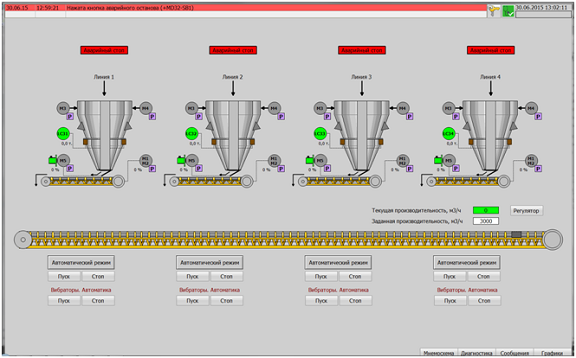

Detailed designed documentation has been prepared and software has been developed for hopper sector control system, unloading device.

Unloading device is used for coal reception from wagons, control of coal unloading, weighing and transporting to the conveyor. Unloading device consists of 4 hoppers 100 m3 each. Automated process control system provides control and monitoring of the following unloading device mechanisms (for each hopper):

- hopper gate;

- vibrator — 2 pcs.;

- vibrating feeder.

The system includes PLCs, frequency converters, operator automated workstation, local and remote control consoles, electric drives for hopper sector mechanisms control, conveyor scales, hopper load cells.

Unloading device control system is used for:

- control of hopper mechanisms of wagon dumpers No.3 and No.4;

- control of coal weight unloaded from the hopper onto conveyors according to reference given by a process operator;

- continuous diagnostics and visualization of the current status of unloading device electrical equipment;

- alarm, visualization and monitoring of process parameters for operators and maintenance staff of unloading device sector.

Equipment designed for hopper sector control system:

- PLC cabinets: PLC30 (PLC of hoppers of wagon dumper No.3), PLC40 (PLC for hoppers of wagon dumper No.4);

- Cabinets of AC drives DAC35, DAC36, DAC38, DAC38 (AC drives for controlling hopper motors of wagon dumper No.3), DAC41, DAC42, DAC43, DAC44 (AC drives for controlling hopper motors of wagon dumper No.4);

- Local control consoles H5+PL. H6+PL, H7+PL, H8+PL (consoles located near hoppers of wagon dumper No.3), H1+PL. H2+PL, H3+PL, H4+PL (consoles located near hoppers of wagon dumper No.4);

- Remote control consoles: MD30 (operator control console of unloading device of wagon dumper No.3), MD40 (operator control console of unloading device of wagon dumper No.4);

- Network equipment cabinet NC34.