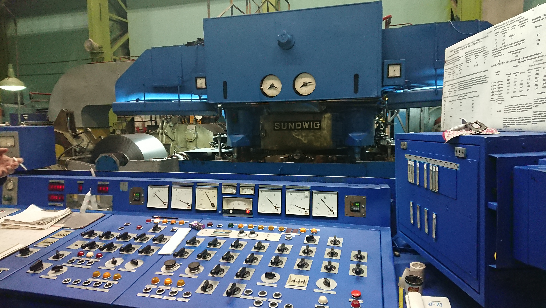

The first stage of revamping of 20-high reversing cold mill Sundwig 720 was successfully completed. The equipment of mill main drives was replaced which was due to multiple failures in equipment operation and obsolescence of control components that entailed regular mill stoppages. For the purpose of revamping the new power units SVPR-1300-460-UHL4 (of CJSC «ASC» manufacture) were developed and implemented. These power units were designed according to the geometric dimensions required and subsequently installed instead of the existing ones while all cable inlets and mounting pads were left as they were which allowed to reduce the time needed for putting the new equipment into service. Then existing analog automatic control systems for mill motor drive and coiler No.1 and No.2 drives DC converter armature were replaced by the new digital converters Sinamics DCM CM, and the analog DC converters of exciters were replaced by the new digital ones: a packaged converter Sinamics DCM — for roll mill stand drive and a built-in converter — for coiler No.1 and No.2 drives. The strip breakage automatic equipment, all counting units for radius, tension and interlocking job assignments were implemented with the use of Sinamics CU320-2DP module. TM15 and TM31 modules were used as analog and discrete signal collection and initialization units. The control module communicates with the drives via OA-Link protocol Sinamics, which provides for the desired system response. The new drive control circuit was integrated into the existent system while using only the components of Sinamics equipment, without the use of controller.

The first stage of revamping of 20-high reversing cold mill Sundwig 720 was successfully completed. The equipment of mill main drives was replaced which was due to multiple failures in equipment operation and obsolescence of control components that entailed regular mill stoppages. For the purpose of revamping the new power units SVPR-1300-460-UHL4 (of CJSC «ASC» manufacture) were developed and implemented. These power units were designed according to the geometric dimensions required and subsequently installed instead of the existing ones while all cable inlets and mounting pads were left as they were which allowed to reduce the time needed for putting the new equipment into service. Then existing analog automatic control systems for mill motor drive and coiler No.1 and No.2 drives DC converter armature were replaced by the new digital converters Sinamics DCM CM, and the analog DC converters of exciters were replaced by the new digital ones: a packaged converter Sinamics DCM — for roll mill stand drive and a built-in converter — for coiler No.1 and No.2 drives. The strip breakage automatic equipment, all counting units for radius, tension and interlocking job assignments were implemented with the use of Sinamics CU320-2DP module. TM15 and TM31 modules were used as analog and discrete signal collection and initialization units. The control module communicates with the drives via OA-Link protocol Sinamics, which provides for the desired system response. The new drive control circuit was integrated into the existent system while using only the components of Sinamics equipment, without the use of controller.

PJSC «Asha metallurgical works», the town of Asha, the Chelyabinsk region.

12.02.2018