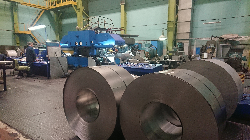

Revamping of 20-high reversing cold-rolling mill Sundwig 720. The second stage of revamping of electric drives and technological automation systems for 20-high reversing cold-rolling mill was completed.

Revamping of 20-high reversing cold-rolling mill Sundwig 720. The second stage of revamping of electric drives and technological automation systems for 20-high reversing cold-rolling mill was completed.

In the course of revamping the electric drives of mill entry and exit rewinders and relevant speed control systems were replaced.

For the purpose of revamping of rewinders’ DC drives the packaged converters Sinamics DCM including both armature circuit and excitation circuit drives were used (the separate power units were used earlier). The TM15 and TM31 modules were applied as analog and digital signal collection and initialization units. Speed control systems were built on two modules Sinamics CU320-2DP: one — for entry and one – for exit rewinder. CU320-2DP modules also include coil radius counting units, tension assignment and job interlocking units. Control modules CU320-2DP communicate with the drives Sinamics DCM via Sinamics OA-Link protocol which provides for the desired system response.

The new rewinders’ control systems were integrated into existent mill automation system Sundwig while using only components of driven equipment Sinamics, without the use of controller. The new rewinders’ control systems allowed to significantly increase the speed of rewind and improve the coil preparation standards for subsequent rolling of thin steel strips.