Automation system for a new mineral fertilizers’ production facility.

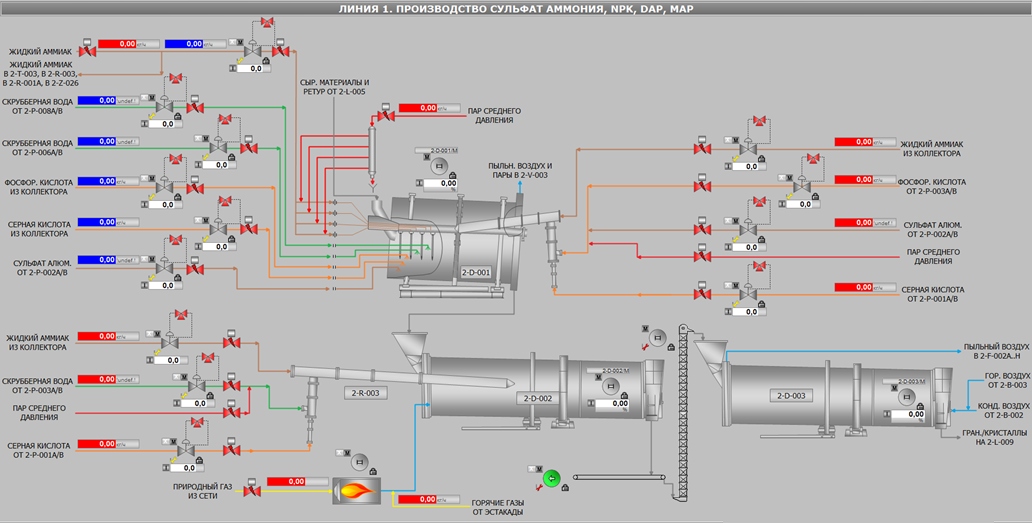

The design activities on implementation of automation system for a new mineral fertilizers’ production facility have been completed for Customer LLC “InvestKhimAgro”. The plant is intended for producing mineral fertilizers with output of 664 thousand tons per year. The ammonium sulphate production building has two processing lines. Owing to flexible process flow design each line is capable of producing the following commercial products:

The design activities on implementation of automation system for a new mineral fertilizers’ production facility have been completed for Customer LLC “InvestKhimAgro”. The plant is intended for producing mineral fertilizers with output of 664 thousand tons per year. The ammonium sulphate production building has two processing lines. Owing to flexible process flow design each line is capable of producing the following commercial products:

- • ammonium sulphate granulas;

- • NPK (monoammonium phosphate sulphates, compound fertilizers);

- • granulated ammonium dibasic phosphate;

- • granulated mono-ammonium phosphate

The scope of «ASC» activities included development of detailed design documentation and application software for each processing line and also for finished products storage area with regard to:

- • overall automation

- • production process automation

The next work stage will be production and delivery of equipment according to detailed design and engineering documentation.

Pursuant to chemical production requirements, the redundancy principle was applied in the design of process control system. For instance, the controllers were fitted out with redundancy functionality which provides for backed-up interface networks and peripheral stations. The process control system has a distributed client-server architecture allowing of its dimensional scaling without heavy capital expenditures. The visual display system consists of the following components:

- • Redundant visual display servers (2 pcs.)

- • Client operator workstations as per work areas (10 pcs.).

- • Engineering station with software design based on distributed control system and emergency shut-down (1 pc.)

- • Web-server.

- • OPC-server.

The above-listed components are virtual machines functioning on two high-end visual display servers.