Replacement of control system for aluminum foil finishing mill FM-4.

The commissioning works on replacement of control system for FM-4 mill have been finished at «RUSAL-Armenal» plant in the Republic of Armenia. The equipment for automated process control system and hydraulic system components were delivered in December, 2022. Erection supervision and commissioning works were fulfilled within the period from January to April, 2023.

In the course of works the mill control system built on basis of controller Vantage and distributed peripheral WAGO, that was put in operation by “VAI” company in the yearly 2000s, was replaced. A new control system is based on automation equipment by “Siemens”.

The activities on changing over to a new control system were complicated by the fact that the mill shutdown period was too short and working on the old controller Vantage, that was a black box for maintenance personnel, presented certain difficulties.

For these reasons the works were conducted in two stages:

Stage 1 – connection to existent automated process control system via Profibus interface with the view of receiving information from existing input-output stations WAGO and comparing the control signals from an old PLC Vantage and a new one S7-1500.

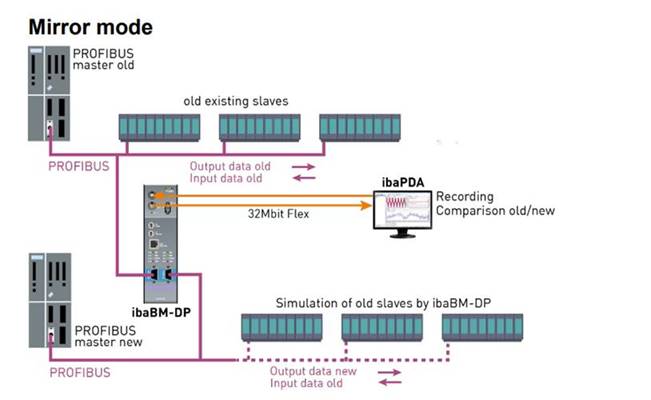

For this purpose the connection to existent Profibus net was established using IbaBM-DP module, set for operation in two modes: «mirror mode» and «ProfiBus sinffer». All signals that were of interest were recorded on Iba PDA server, post-implementation review of control systems was carried out, thickness gage and roll selective cooling system were adjusted using a new PLC S7-1500 software.

The example of communication organization in «mirror mode»:

At this stage communication with existent thickness gage by “Honeywell” was tested too using OPC server. The dedicated software – OPC gateway Coagent, required for connection of OPC-DA server of thickness gage to OPC-UA server of S7-1500, was used for that purpose.

Based on the results of the first work stage the decision was taken to pass over to the second work stage.

Stage 2 involved removal of old control system based on PLC Vantage and commissioning of a new control system based on PLC Siemens S7-1500.

The works conducted resulted in putting into operation of a new mill control system built with the use of the following components:

- • PLC S7-1500;

- • remote input-output stations ET200SP;

- • engineering station with software Siemens TIA Portal;

- • archive server Iba PDA;

- • operator’s visual display station based on TIA WinCC Professional RT;

- • existent thickness gage by “Honeywell”;

- • data exchange with existent controller for auxiliary mechanisms that was provided using ProfiBus coupler.