Automation of railway transport is the right path forward to developing your business.

An unsophisticated inhabitant of Central Russia is unlikely to have any associations when hearing the word combination “Kimkano-Sutarsky Mining and Processing Plant”. The enterprise is situated at a distance of more than 8 000 km from Moscow, if you travel by auto-road, in the Far East in the Jewish Autonomous Region near the city of Birobidzhan. Nevertheless, Kimkano-Sutarsky Mining and Processing plant or KSMPP, for short, is one of the leaders of the regional economy: production capacity of the first stage is 10 million tons of run-of-mine ore per year and 3,2 million tons of iron-ore concentrate with a 65 % iron content. KSMPP is a relatively young and fast developing enterprise, the construction of which began in 2007, and a full-fledged production start took place in 2017. Currently the enterprise rapidly develops the project referred to as «Sutarskoye itabirite deposit». Initial mine development» Stage II. «Sutara» quarry mining Stage I.»

No sooner had the ceremonial events dedicated to celebration of the Metallurgist Day taken place than works began to complete the project on automation of the «Promyshlennaya» railway station. The station caters for the final process of the technological chain – loading of finished products (iron-ore concentrate) into rail cars, generation of exit routes and dispatch of railway trains to the public-use rail network. The station also receives trains with empty cars and various cargoes for the needs of KSMPP. The company management has made the right choice in favor of microprocessor interlocking system MIS-ASC. The interlocking covers: 5 electrified receiving and departure tracks for exchange of trains with the Connecting station involving coding of rail track circuits, 7 tracks and track stubs of various purpose, 23 of 31 track switches, two-way semi-automatic interlocking with the «Izvestkovaya» station belonging to OAO «Russian Railways» («RZD»).

No sooner had the ceremonial events dedicated to celebration of the Metallurgist Day taken place than works began to complete the project on automation of the «Promyshlennaya» railway station. The station caters for the final process of the technological chain – loading of finished products (iron-ore concentrate) into rail cars, generation of exit routes and dispatch of railway trains to the public-use rail network. The station also receives trains with empty cars and various cargoes for the needs of KSMPP. The company management has made the right choice in favor of microprocessor interlocking system MIS-ASC. The interlocking covers: 5 electrified receiving and departure tracks for exchange of trains with the Connecting station involving coding of rail track circuits, 7 tracks and track stubs of various purpose, 23 of 31 track switches, two-way semi-automatic interlocking with the «Izvestkovaya» station belonging to OAO «Russian Railways» («RZD»).

Apart from the main objective, that is: ensuring traffic safety and shunting operations, enhancing loading and processing capacity of the station, the following additional tasks were accomplished as part of the project:

- – displaying the number of cars, being on the track, on the station’s mimic diagram, thus improving control over shunting operations and facilitating monitoring of the transport operation;

- – integration with the enterprise information systems, which allows of data exchange and display of the station’s mimic diagram in real-time mode at any workplace within the enterprise network, thus increasing “transparency” of logistics for the production.

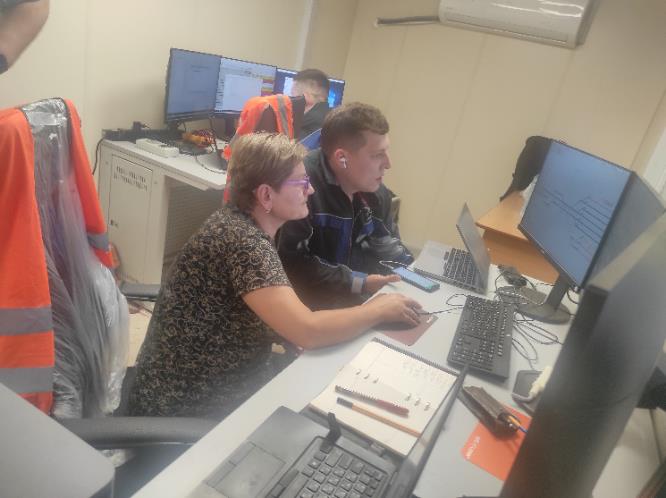

Another challenging task, set by the manager of the project on the station modernization, was to conduct training for railroad transport workers directly at their workplaces, followed by issuance of nationally recognized certificates. In order to do that, we, together with the Magnitogorsk State Technical University, named after G.I.Nosov (one of few higher educational institutions that has an extensive experience in training of skilled workers specifically for industrial railway transport), have developed the two competence development programs:

- — Organization of railway transport control with rolling stock placement using hardware and software package «MIS-ASC»;

- — «Operation of systems ensuring train movements and shunting based on microprocessor interlocking with the use of axle counting system «MIS-ASC».

The training process was combined with commissioning activities, and this has brought excellent results. The theoretical material was instantly backed up by practical tasks directly on the equipment to be subsequently handed over to the customer; thus the Interlocking service engineers were, as early as the training stage, well-versed in electronic axle counting devices, MIS cabinets and equipment monitoring software (the workstation of the station duty electromechanical technician). For the train service a simulator of the station duty officer workstation was developed, duplicating the functions of a working version for the «Promyshlennaya» station, which was conducive to speeding up and facilitating the process of changing over to microprocessor control from the manual one. By using a simulator the station duty officers familiarized themselves with the special aspects of the station elements’ visualization, ways of managing the track switches and setting the routes; certain emergency situations were studied carefully too. Thus, by the time of changing to the station control via the station duty officer workstation, the station duty officers already had a grip on working with new equipment and were well-versed in software. It is worthwhile noting that the time it took the station duty officers to freely and confidently manage the shunting operations under this approach to training was 1-3 hours.

The training process was combined with commissioning activities, and this has brought excellent results. The theoretical material was instantly backed up by practical tasks directly on the equipment to be subsequently handed over to the customer; thus the Interlocking service engineers were, as early as the training stage, well-versed in electronic axle counting devices, MIS cabinets and equipment monitoring software (the workstation of the station duty electromechanical technician). For the train service a simulator of the station duty officer workstation was developed, duplicating the functions of a working version for the «Promyshlennaya» station, which was conducive to speeding up and facilitating the process of changing over to microprocessor control from the manual one. By using a simulator the station duty officers familiarized themselves with the special aspects of the station elements’ visualization, ways of managing the track switches and setting the routes; certain emergency situations were studied carefully too. Thus, by the time of changing to the station control via the station duty officer workstation, the station duty officers already had a grip on working with new equipment and were well-versed in software. It is worthwhile noting that the time it took the station duty officers to freely and confidently manage the shunting operations under this approach to training was 1-3 hours.

The entire commissioning process took a little less than 2 weeks, of which most of the time was spent on preparatory and testing work, and as for integration of signaling arrangements into MIS system itself, when the train service engineers ultimately had a full-fledged station control tool, it took 2 days only. A good result for the production in operation!

The entire commissioning process took a little less than 2 weeks, of which most of the time was spent on preparatory and testing work, and as for integration of signaling arrangements into MIS system itself, when the train service engineers ultimately had a full-fledged station control tool, it took 2 days only. A good result for the production in operation!

The team of JSC «ASC» and FSFEI HE «MSTU named after G.I.Nosov» offers its sincere congratulations to the Kimkano-Sutarsky Mining and Processing Plant on the occasion of start-up of microprocessor-based interlocking at the «Promyshlennaya» station and wishes never ever stop on the way of improving the efficiency of business!