Automated process control system for continuous-casting machine No.2.

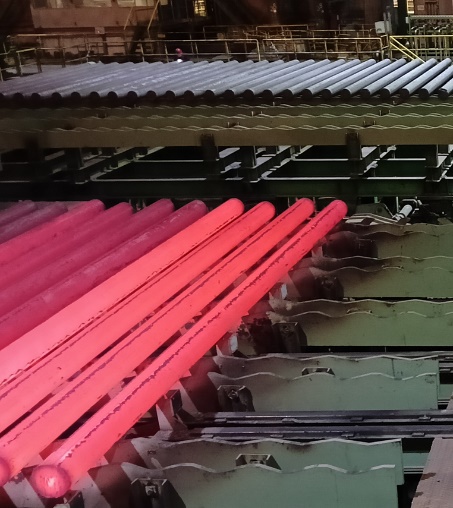

Our company’s specialists, in collaboration with the specialists from the State Science Center FSUE I.P.Bardin Ferrous Metallurgy Research Institution, have put into operation a 4-strand continuous bloom caster No.2 in electric steel-making shop at Volzhky Pipe Plant (within the framework of the “Unstainable river” project).

The commissioning activities involved three main phases:

-

Start-up and adjustment activities outside the erection area. The JSC ASC specialists, with the support of the specialists from the State Science Center FSUE I.P.Bardin Ferrous Metallurgy Research Institution and Volzhsky Pipe Plant, accepted the electric equipment cabinets, assembled according to JSC ASC design, in China. During the acceptance procedure the equipment certification was carried out, voltage was supplied to all control cabinets, signals were tested with motor cranking from frequency converters under control of visual display system of a continuous-casting machine.

- Supervision of erection of electrical equipment at the site of Volzhsky Pipe Plant.

- Application software debugging along with cold and hot testing, performance of warranty tests, equipment handover to commercial operation.

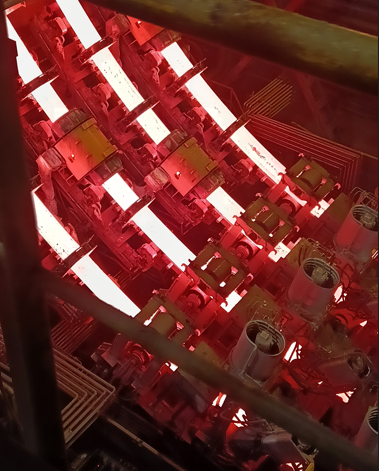

The control system for continuous-casting machine and auxiliary mechanisms is built on basis of 6 programmable controllers:

- ► common PLC – implements the functions of control of mechanisms of a casting platform and basic data exchange with third-party packaged systems;

- ► strand PLCs – control of cooling and transfer of a continuous cast billet (4 pcs.);

- ► exit end PLC – control of weighing and transfer of billets to the billet yard.

The mechanisms of continuous-casting machine are driven by more than 100 frequency converters and soft starters.

The automation system is a two-level one. The first level is PLC and visual display system, for control of mechanisms via operator workstation and output of necessary diagnostic information to the workstation. The second level is billet tracking, report generation and exchange with a factory manufacturing execution system.

Both the first- and the second-level visual display systems employ the virtualization technology. The redundant servers are made use of for reliability enhancement.