In July, 2021 the specialists of CJSC «ASC» finished works on implementing the Automated metal tracking system on cut-to-length lines 2, 3, 4, 650 in Metal working center No.2.

The works under the project commenced in the beginning of 2020. The project actually included the two of activities:

The works under the project commenced in the beginning of 2020. The project actually included the two of activities:

- Reconstruction of cut-to-length system on cut-to-length lines 2 and 3.

- Creation of automated metal tracking system on cut-to-length lines 2, 3, 4, 650.

Cut-to-length control system is intended to automate the process of strip cutting to length with a high degree of accuracy and destacking into sheet piler bins. The system includes two functional subsystems:

• Cutting to length subsystem.

• Automatic tracking and destacking subsystem.

Main functions of cutting to length subsystem:

- Entry and display on control desk No.2 of a preset length of the sheets and tolerance;

- Strip cutting to sheets of an arbitrary assigned length;

- Monitoring the length of the cut sheets for compliance with tolerance;

- Cutting of particular strip areas to short lengths of a fixed size at the operator’s signal;

- Cutting of particular strip areas to off-gage short lengths at the operator’ signal (manual cutting);

- Cutting of a strip front end and bottom end;

- Indication of a length of the cut sheets and signaling on control desk No.2 in case the length exceeds tolerance.

Main functions of automatic tracking system:

- Entry and display on control desk No.3 of a preset quantity of sheets in piles, coordinates of release point and operating parameters of sheet trimmers for sheet pilers No.1,2,3.

- Counting and indication on control desk No.3 of the current quantity of sheets in piles of sheet pilers No.1,2,3.

Sheet distributing between sheet pilers No.1,2,3 at the operator’s initiative and (or) automatic switching (change-over) of sheet flow between sheet pilers No.2,3 when a preset quantity of sheets in piles is reached. Control of the machines is executed via existent control pulpits by means of control and indication elements and operator workstation.

The reconstruction contributed to increase of accuracy and stability of coil cutting and made the plant operator’s job easier.

Automated metal tracking system used on cutting lines is intended for:

- Data collection from machines and systems of the cutting lines.

- Automatic traceability of a product unit.

- Visualization of a product unit making its way along various assembly parts of the plant.

- Providing a process staff with data required for product manufacture and attestation.

Automated metal tracking system ensures the fulflment of the following functions:

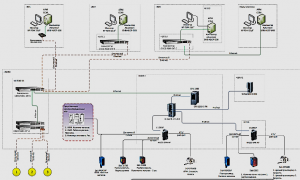

• The function of bidirectional information integration with related systems of Level 2 (Flatness, Camber, Parsytec, Ultrasonic check, 3D Warehouse) and record keeping systems of Level 3 (QMet, Autoattestation).

• The function of production planning, according to the production programme.

• The function of preliminary expert metal quality assessment.

• The function of visualization.

• The function of report generation.

Implementation of metal tracking system has given an opportunity to determine the volume of rejected products at the early stage, improve the sales order schedules and reduce the coefficient of materials consumption due to more careful planning of production lot to be launched under specific sales order.