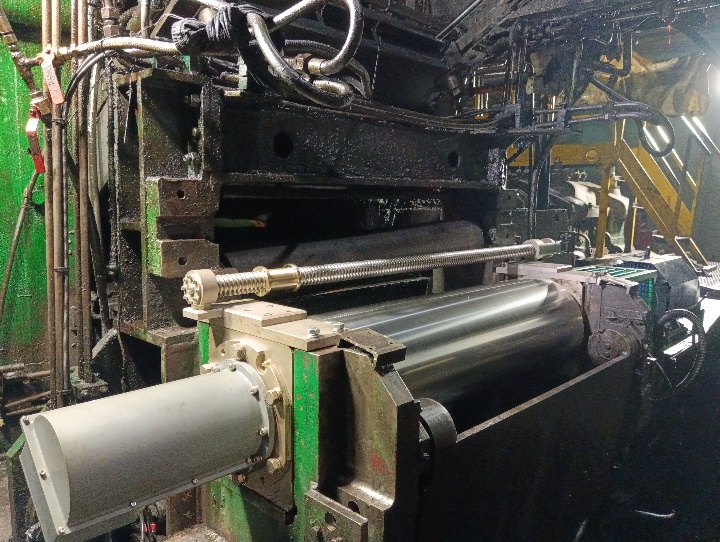

Implementing the shape measuring system for 4-high single-stand rolling mill 1200.

The company engineers have fulfilled the works on design, delivery and commissioning of the shape meter system for 4-high single-stand rolling mill 1200, operated in transformer steel shop at PAO NLMK (Public Joint Stock Company).

AO ASC (Joint Stock Company) is an authorized partner-integrator of POWER MnC Co., Ltd company, specializing in production of shape meter systems, and provides the following services for the afore-mentioned systems:

- — engineering,

- — sales and marketing in the territory of Russia and neighboring countries,

- — commissioning,

- — after-sales and warranty service.

The following activities were carried out: pre-design negotiation and approval of shape meter system parameters for mill 1200, equipment acceptance in the territory of the manufacturing plant, delivery, erection supervision, commissioning and integration of the shape meter system into the mill control system.

The mechanical scope of the project with regard to binding the measuring roll and air supply panel was performed by our partner company — AO Scientific Industrial Enterprise Mashprom (Joint Stock Company). AO ASC (Joint Stock Company) performed integration of software interface with the existing mill control system, implemented a project for replacement of a variable-frequency drive and the electrical part.

The shape meter roll for mill 1200 has the following parameters:

- — Quantity of sensors per measuring zone: 4 pcs/rotation (90 degrees spacing).

- — Roll diameter: 400 mm.

- — Roll width: 1200 mm.

- — Sensor coverage width: 1150 mm.

- — Quantity of measuring zones: 23.

- — Measuring zone width: 50 mm.

- — Measuring precision: 0,5 I-unit.

- — Surface hardness: 54 HRC.

Rolling parameters:

- — Grain-oriented electrical steel.

- — Operating mill speed: 480 m/min.

- — Strip gage: 0,6-0,85 mm.

- — Strip width: 750-1050 mm.

- — Tension range: 50…147 kN.

- — Strip temperature: < 260 Celcius degree.

The quantity, width and location of measuring zones were chosen according to the selective roll cooling system already-present on the mill. Roll diameter 400 mm is a customized one to replace an existing bending roll. Bearing assemblies were developed by the custom order too.

Equipment configuration of the system as delivered and installed is as follows:

- — Measuring roll.

- — Signal transmission board STU (installed on the roll).

- — Shape measuring panel.

- — New electric motor and coupling.

- — Plate for installing the electric motor and speed sensor.

- — Air supply panel for measuring roll.

- — Calibration device with electric drive for positioning the calibration weight.

- — Variable-frequency drive panel.

- — Remote shelter display to be installed above the existing exit operator’s console.

- — Spare tools and accessories kit.

Besides, at customer’s request, the following auxiliary functions were implemented:

- — Exchange with shop production management system.

- — Display of a preset flatness curve shape on the operator’s workstation screen.

- — Collection of historical data on coils for further analysis.

Now that the PSM-2000 system is installed, the customer is able to monitor the shape of the strip being rolled and promptly correct it, when required, using the systems, already existing on the mill: the system of controlling the cylinder skew of hydraulic screwdown structures and the system of controlling the coolant feed to roll cooling zones.