Modernization of electrical equipment for the finishing line of bar-rolling mill shop – stage II.

The second stage of modernization involved upgrading the central control room for oil and grease lubrication systems, hydraulic units, pressurized water stations and drain pumps of bar-rolling mill (central lubrication station), as well as electric drives of roller tables in the straightening machine area, electric drive of the straightening machine itself and several control systems of auxiliary mechanisms in the finishing line area.

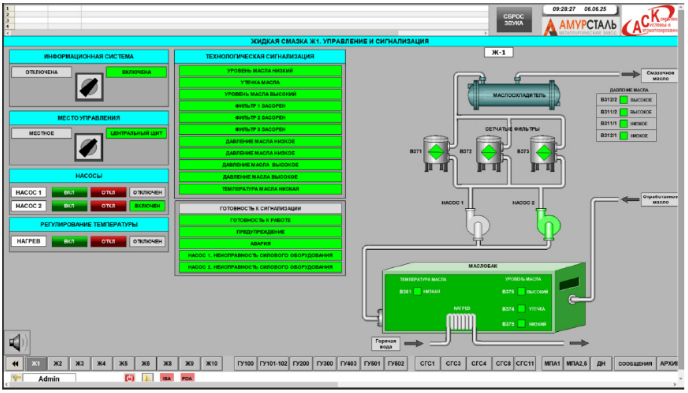

The central lubrication station is located in a dedicated electrical room of the mill (ER SR2) and is designed for remote monitoring and control of the following systems of bar-and-wire rolling mill 320/150:

- — nine oil lubrication systems of the mill (Ж1-Ж6, Ж8-Ж10);

- — five grease lubrication systems (СГС1, СГС3, СГС4, СГС8, СГС11);

- — eight hydraulic units of the mill (ГУ100, ГУ101, ГУ102, ГУ200, ГУ300, ГУ403, ГУ501, ГУ502);

- — two pressurized water stations (1MPa and 2,5MPa);

- — five drain pumps (mud water pumps).

Instead of a board with mnemonic panel and hardwired controls the automated workstation (AWS) for central lubrication station was installed, equipped with two monitor displays and connected to a HMI-server installed during the first stage of modernization.

At the locations where there used to be the mnemonic panel boards of central lubrication station, now removed from service, the field stations manufactured by Odot (PRC) were installed.

In five oil cellars and three hydraulic cellars of the mill the old local control panels for the above-listed systems were replaced.

Modernization of central lubrication station was carried out under conditions of a 12-day complete shutdown of the mill (a scheduled annual major repair).

Some of the field stations of central lubrication station had been pre-installed during the first stage of modernization, which contributed a lot to faster commissioning of a new hardware-software complex of central lubrication station.

All field stations within the area of operation of central lubrication station were connected via Profinet buses to SA30 controller (CPU1518-4PN/DP) for the finishing line and central lubrication station, which had been installed and commissioned during the first stage of modernization.

Following the modernization scheme, devised and agreed upon with the managerial staff of OOO Amurstal (Limited Liability Company) and bar-rolling mill shop, immediately after completing a set of works (dismantling of old equipment, installation of new electrical equipment, laying of new cables, debugging of software), related to introducing a new hardware-software complex (HW-SW) of central lubrication station and scheduled repair of the mill, an eight-day wire rolling campaign was arranged, heralding the start of modernization of electrical equipment in the finishing line area.

Most of the works on dismantling of old and installation of new electrical equipment in the finishing line area took place during the period of a 12-day major repair of the mill.

During an 8-day wire rolling campaign the following volume of work was performed.

A complete (incl. power reversible thyristor bridges of armature circuits and motor excitation winding supply) analog automatic control system of the regulatory type for DC drive of the straightening machine was taken out of service.

A new complete digital unit enabling microprocessor control of a DC drive, based on a Sinamics DCM counterpart, namely, the complete DC converter "VARIANT DC", was installed in place of a dismantled cabinet assembly.

The complete analog frequency converters of AC drives were decommissioned.

- — outgoing roller table (before straightening machine, group 1);

- — outgoing roller table (before straightening machine, group 2) and charging roller table of the straightening machine;

- — roller table at the exit of the straightening machine and runoff table, group 1;

- — roller table at the exit of the straightening machine, group 2;

- — standby FC for outgoing and runoff roller tables.

New cabinets containing the complete microprocessor-controlled digital frequency converters (FC), based on Inovance MD880 (Single Drive), were installed in place of the dismantled analog FC cabinets.

A new digital automatic control system of the regulatory type for the straightening machine’s electric drive, digital FCs for roller tables in the straightening machine area and the field station Odot, mounted instead of the old panel and intended for quick switching from any working FC of the roller tables to the standby FC, were connected via Profinet buses to the SA30 controller (CPU1518-4PN/DP) of the finishing line and central lubrication station.

Throughout all stages of work, including amendment of design and engineering documentation, piping and instrumentation diagrams and fixing of software for modernization of electrical equipment of the finishing line area and central lubrication station of mill 320/150, the ASC specialists received technical and organizational support from the operating personnel of automation and electric drive divisions of the bar-rolling mull shop, managerial staff of the shop and managerial staff and experts of project management and procurement departments of OOO Amurstal (Limited Liability Company).